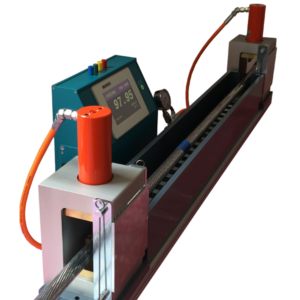

The precision holding device PWD 3000 is used for the determination of the electric resistance per meter of power and medium voltage cables. The measurement is based on the 4-pole method according to Kelvin in order to eliminate the feed line resistances.

The measuring current is supplied via pneumatically operated jaws, the measuring voltage picked-up via spring-supported taps, with a distance between the taps of 1000 mm (+/- 0,2mm).

The current jaws and thus the current feeding points are arranged at a sufficient distance to the taps in accordance with DIN / IEC to ensure a constant and uniform distribution of the current across the actual measuring distance. The cable section is placed in two inner troughs which are filled with flowing water when the pump is running and are containing the potential bars for picking up the measuring voltage; it is here where the actual measurement takes place at a constant (water-) temperature.

The Microohmmeter which is part of the equipment additionally measures the (water-) temperature via a probe, and converts the previously measured resistance value to 20°C (or e.g. 23°C if wanted).

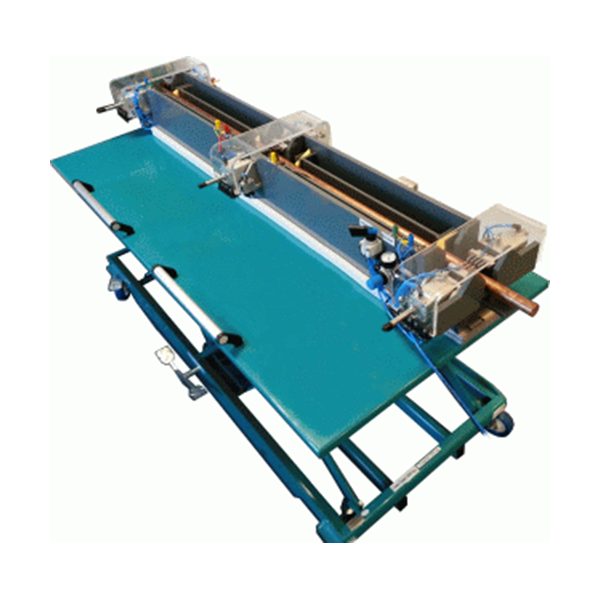

The standard holding device PWD 3000 Cu is suitable for copper cables (stranded cables and sector-shaped conductors) of a size between 10mm² and 1200mm² (Ask for larger sizes!).

The PWD 3000 Cu-Al allows the measurement of aluminium cables (round and shaped conductors). The design is more complex than the the standard variant in order to include all wires of the cable into the measurement. This is necessary due to a potential anodized situation inside the cable.

The Microohmmeter which is part of the equipment contains double measurement inputs for resistance and temperature (PT100). It allows with its waterproof touch panel the selection of resistance range (including auto range), reference temperature, cable idenfication, setting/locking parameters and tests of the whole equipment with a calibrated reference rod. Interfaces are for printer, USB and LAN (optional).

The outer trough serves as a water reservoir. The current jaws, the pneumatic equipment, the pump, all connections, etc. are provided on a massive, twist-proof aluminium rail or lift table outside of the outer trough and are therefore not exposed to the water.

| Measuring distance Length of test object Diameters (Model 2000): Diameters (Model 2040): Diameters (Model 3000): | 1000 mm ± 0,2 mm > 1350 mm 10 mm² - 1200 mm² 30 mm² - 2000 mm² 30 mm² - 1200 mm² |

| Measuring current | 50 A max. |

| Water capacity approx. 15 l Circulation Circulation pump Zuleitungskontakten Fehler bei Potentialkontakten Bereichsüberschreitung >80% Thermospannungskompensation | integrated water flow system 230 V AC or 115 V AC |

| Pneumatic Nominal pressure 8 bar Holding / release of test object Security Longitudinal feed force (model L) | by switch (open / close) Holding procedure only by closing covers selectable |

| Model overview: | |

| PWD 2000 P | no longitudinal tension device provided |

| PWD 2000 P / L semi-autom. | the tensile force required can be adjusted via a control device (control knob with calibration). The force required must be looked up in a table. Reproducible tensile forces and thus reproducible measurements are possible. |

| PWD 2000 P / L automatic | design as with semi-automatic device, but the resistance value and thus the cross-section of the cable is determined first by the MR300C-A MICROOHMMETER, then the corresponding tensile force is looked up in an internal table and applied via an electropneumatic actuator. The following second measurement is the correct measurement which is displayed. This enables easily reproducible measurements without any human errors. The table can be entered or modified into the instrument via a computer and is stored even when the instrument is switched off. The user will be responsible for this table. |

| PWD 3000 Cu / Cu-Al | For non isolated stranding machines. No longitudinal tension is provided |

- Holds diameters from 10 mm² to 1200 mm²

- Current max. current 50 A

- Integrated water flow system for homogeneous object temperature during measurement

- Acryl covers for secure operation

- Can be connected to any air pressure system providing 8 bar

- Model PWD 3000 Cu for copper

- Model PWD 3000 Cu-Al for Aluminium and Copper

- Microohmmeter MR 300 C-A:

The ideal instrument in conjunction with this holding device. - Software MR300C-A XFER

sends measurement values to any Windows© application. Including special Excel© functions. For Windows© 95 / 98 / NT / ME / 2000. - Temperature probe 5 °C to 60 °C

- Sacrifical anode against long-term corrosion

- Special diameter rebuild:

possible by request

- Cable 4pole, various lengths,

banana plugs (4x, red, yellow, green, blue) - Calibrated testpattern calibrated by DKD

(‚Deutscher Kalibrierdienst‘)

DIN EN ISO 9001:2008